Made out of m390 Steel with a waterjet profile and hand-ground edge & blade.

This beast is made out of Bohler m390 Microclean Steel (seriously, check out the datasheet at the link, its some incredible stuff). I cut the profile of the knife on a waterjet cutter. I then cut the handle pieces out of Kirinite on the same machine. Kirinite is a really cool blended acrylic material (Made in America!). It is really easy to work with (it machines like butter), and it yields some really cool patterns- especially if you use their layered material. It sands and polishes beautifully, and is a perfect material for kickass knife handles or gun grips. Anyway, that plug aside, after cutting the profile of the blade and two handle pieces, I was left with about 8 hours of grinding (like I said, m390 is tough). After that came a ton of sanding, installing hardware in the handle pieces, and matching the handle to the tang of the knife. Then, of course, 6+ more hours of sanding and polishing. After that came heat treating (great place in PA called Peter’s Heat Treating– entire job only cost ~$25). Next came sharpening and, you guessed it, 12 more hours of polishing. I’ve added some photos of the process and the final product below!

- The initial design

- The raw bar of m390

- Blade and handle profiles cut out

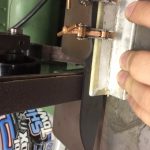

- The blade clamped to a piece of angle stock for grinding

- Grinding!

- One side down

- Matching the handles to the tang

- The polished blade

- All done!